gold baR MOLD

Volcano Corporation crafts gold bar mold from high-quality graphite, specifically designing them for casting precious metal ingots in a vacuum gold bar machine. These molds come in various sizes and forms, including four-in-one, two-in-one, and single bar molds, each equipped with a lid. They are suitable for all gold ingot casting capacities, from small to large, ranging from 100g to 1kg.

Volcano Corporation gold bar molds are often made from fine-grain graphite, machined from solid graphite bars. This material provides a very smooth finish, ensuring that the precious metal ingots have a clean and polished appearance.We use graphite molds to cast ingots of gold, silver, copper, platinum, and other metals.

The durability of Volcano Corporation gold bar molds makes them highly recommended for casting ingots in precious metal foundries and various mechanical industries. These molds are cost-effective and long-lasting, offering excellent thermal resistance, corrosion resistance, good thermal conductivity, and resistance to acidity and alkalinity. Additionally, they are impact-resistant, energy-saving, and allow for easy removal of ingots after casting. The ingots produced with these molds are of high quality and durability.

- parameters

- features & benefits

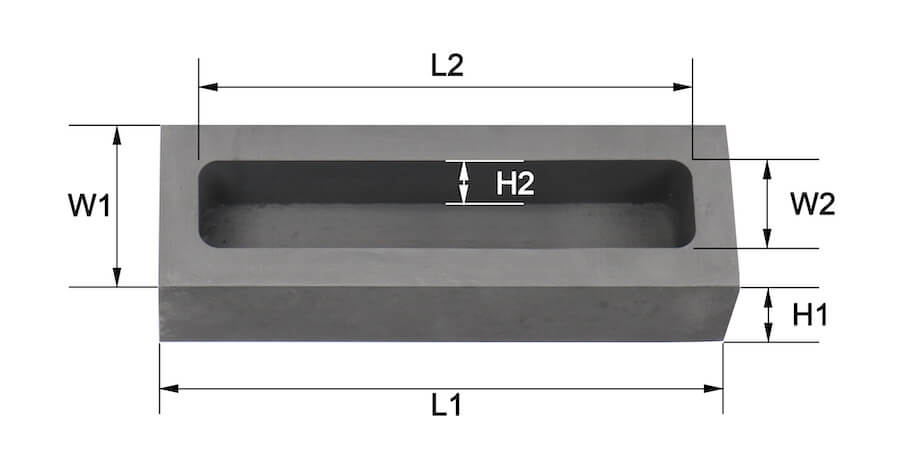

| Description | Model | Size | |||||

| L1 | W1 | H1 | L2 | W2 | H2 | ||

| 100g graphite ingot mold | G.GI.Y0100 | 55 | 40 | 20 | 35 | 20 | 10 |

| 200g graphite ingot mold | G.GI.Y0200 | 70 | 45 | 20 | / | / | / |

| 250g graphite ingot mold | G.GI.Y0250 | 67 | 50 | 26 | 47 | 25 | 16 |

| 300g graphite ingot mold | G.GI.Y0300 | 70 | 57 | 20 | / | / | / |

| 400g graphite ingot mold | G.GI.Y0400 | 75 | 67 | 20 | / | / | / |

| 500g graphite ingot mold | G.GI.Y0500 | 70 | 67 | 26 | 50 | 47 | 16 |

| 1kg graphite ingot mold | G.GI.Y1000 | 135 | 42 | 32 | 115 | 22 | 22 |

| 2kg graphite ingot mold | G.GI.Y2000 | 160 | 48 | 38 | 140 | 28 | 28 |

| 3kg graphite ingot mold | G.GI.Y3000 | 175 | 52 | 42 | 155 | 32 | 32 |

- Volcano Corporation gold bar molds offer excellent thermal stability, making them suitable for both emergency heat and cold usage conditions.

- The mold offers excellent resistance to corrosion, acids, and alkalis. This ensures that it can cast a variety of metals, regardless of their chemical properties.

- Precious metals stay uncontaminated during casting with a gold bar mold because the mold integrates its physical and chemical properties seamlessly.

- The smooth cavity finish of the gold bar mold facilitates easy removal of gold ingots after casting.

- The gold bar mold demonstrates excellent thermal stability, capable of withstanding the high temperatures of molten metals. It maintains its size and does not expand or contract when exposed to heat.

- Gold bar molds find extensive use across various industries, including foundries, metallurgy, chemicals, mechanical engineering, and electrical power. They are also suitable for applications such as continuous casting, pressure foundry molding, glass molding with dies, sintering, centrifugal casting, and the smelting of gold and silver.

- Gold bar molds, crafted from high-density fine-grain graphite, handle multiple casting capacities within a single mold.

- The graphite used in gold bar molds contains less than 0.1% ash, ensuring that your precious metals remain uncontaminated during the casting process.

- The Volcano Corporation gold bar mold can also serve as a graphite crucible for melting nonferrous metals, for test analysis, and as an ingot mold.

- Our gold bar molds are among the most heat-resistant materials available, providing excellent thermal shock resistance. They will not crack, regardless of whether the temperature is high or low.

- The gold bar mold boasts outstanding thermal conductivity and excellent conductive properties, which are key features of its design.

- The mold features excellent self-lubrication, which facilitates the easy removal of gold bars after casting, and it also offers strong abrasion resistance.