granulation making machine

what is granulation machine ?

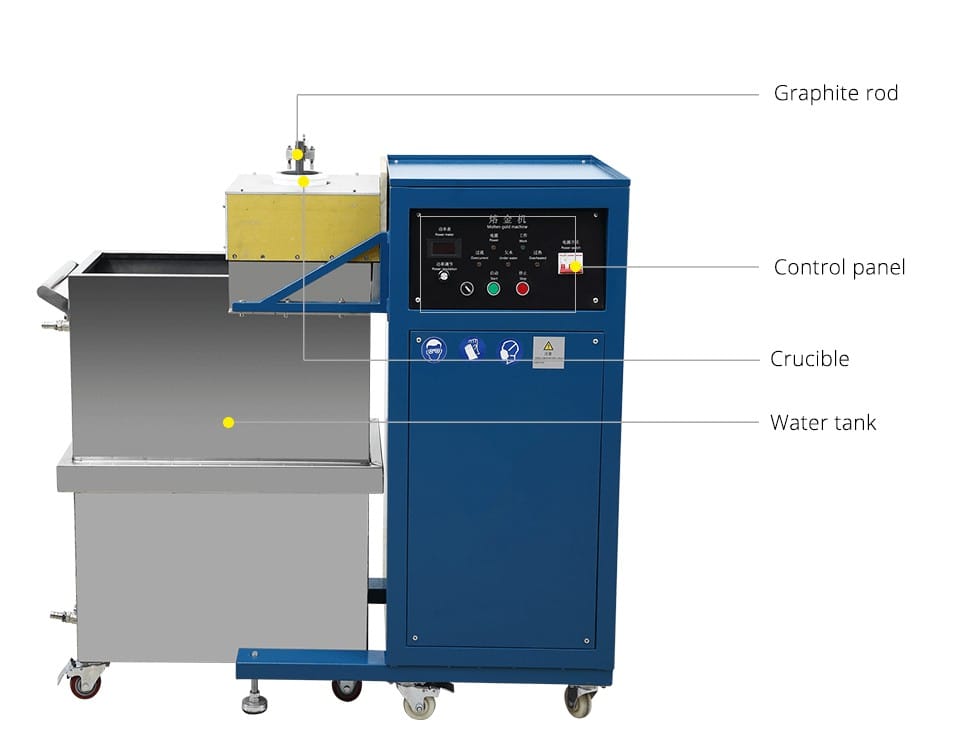

The metal granulating machine combines metal smelting and granulation to produce metal particles such as gold, silver, and copper. It can produce 5 to 100 kg of metal particles and primarily serves metal recycling and processing plants. Operators melt the metal material to create liquid metal, which they then flow into a mold with holes to form irregular metal particles.

The Volcano Corporation metal granulator features a simple structure and uses induction melting technology, which provides a faster and more stable melting speed. Its cost performance is high, making it a good choice for many metal processing plants.

- parameters

- features

- application

| Model number | vc – gm 1 | vc – gm 2 | vc – gm 3 | vc – gm 5 |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 15 kw | 20 kw | 25 kw | 30 kw |

| Applicable metal | Gold, K-Gold, Silver, Copper, Brass, Bronze | Gold, K-Gold, Silver, Copper, Brass, Bronze | Gold, K-Gold, Silver, Copper, Brass, Bronze | Gold, K-Gold, Silver, Copper, Brass, Bronze |

| Casting method | Gravity granulation | Gravity granulation | Gravity granulation | Gravity granulation |

| The Max capacity | 24K Gold : 1.0 kg 925 Silver : 1 kg | 24K Gold : 2.0 kg 925 Silver : 2 kg | 24K Gold : 3.0 kg 925 Silver : 3 kg | 24K Gold : 5.0 kg 925 Silver : 5 kg |

| Casting material | Particles | Particles | Particles | Particles |

| Dimension | 1200 * 530 * 1200 mm | 1200 *530 * 1200 mm | 1200 * 530 * 1200 mm | 1200 * 530 * 1200 mm |

| Weight | 150 KG | 180 KG | 220 KG | 270 kg |

Automatic Tracking Frequency

The machine automatically tracks frequency, making the melting process more stable and safe. It operates quietly, shortens granulation time, and significantly improves production efficiency.

Solid-State Technology

The machine uses solid-state technology and incorporates the latest and most advanced IGBT module available. PID technology ensures accurate temperature control, enhancing the quality of the finished product.

PLC Control System

The touch screen operation simplifies control, making it more convenient to use with clear parameter settings.

Convenient Material Fetching

The separation arrangement of the material box and the water tank allows for easy collection of materials; consequently, once granulation is complete, retrieving the materials becomes straightforward.

Multi-Holes Design

The mold features multiple holes, which speeds up the granulation process.

Multiple Protection

The machine includes a comprehensive protection system. It activates fault lights and alarms in the event of overcurrent, overvoltage, excessive temperature, or short circuits, providing timely alerts to employees and reducing operational risks.

Continuous Work

The machine allows for continuous feeding. After completing the first batch of smelting, operators can continue feeding material into the smelting furnace without stopping the machine, facilitating mass production and increasing efficiency.

A metal granulating machine is capable of producing a variety of metal particles, which can be further processed or cast. The particles’ shape allows them to be more easily molded or formed into final products, making the machine highly valuable in metal recycling, refining, and casting industries.

Mining Industry

These machines are used to process raw metal ores and concentrates, yielding high-quality metal products.

Foundry Industry

They play a key role in metal casting and forging, where metal alloys are melted and granulated for use in casting and forging operations.

Manufacturing Industry

Metal granulating machines are employed in the production of metal products like wire, rods, bars, and sheet metal, supporting various manufacturing applications.