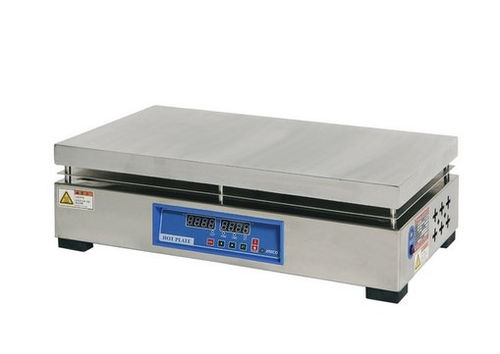

industrial hot plate

| plate size | ratings |

| 12″ x 12″ | 1.2 K.W. |

| 12″ x 14″ | 1.5 K.W. |

| 14″ x 16″ | 2.0 K.W |

| 14″ x 18″ | 1.0 K.W. |

| 14″ x 22″ | 1.2 K.W |

| 16″ x 24″ | 2.0 K.W. |

| 16″ x 28″ | 3.0 K.W. |

what is industrial plate and it’s uses in hallmarking .

Definition: Industrial hot plates are specialized heating devices used in various industrial applications to provide consistent and controlled heat. They are designed to heat materials or equipment uniformly and are often used in laboratory settings, manufacturing processes, and other industrial environments.

Key Features:

- Temperature Control : They come with precise temperature control mechanisms, often with digital readouts for accuracy.

- Uniform Heating : Designed to heat surfaces evenly to prevent hot spots.

- Durable Construction : Typically built with robust materials to withstand heavy use and high temperatures.

- Safety Features : May include features like overheat protection and automatic shutoff.

Uses in the Hallmarking Process

Hallmarking Process: Hallmarking is a certification process for precious metals (like gold, silver, and platinum) that verifies their purity and authenticity. This process involves several steps where industrial hot plates can play a crucial role:

- Melting Metal:

- Application : Industrial hot plates are used to melt small quantities of metal samples during the hallmarking process. Accurate temperature control ensures that the metal reaches its melting point without overheating.

- Benefit : Ensures consistent melting temperatures for accurate testing and analysis.

- Sample Preparation:

- Application : After melting, the metal needs to be kept at a specific temperature for casting or testing. Hot plates provide a stable heating source to maintain the metal’s temperature.

- Benefit : Helps in preparing the metal samples consistently for testing or casting.

- Testing and Analysis:

- Application : During the testing phase, such as when conducting assays or chemical tests to determine metal purity, hot plates can be used to heat solutions or samples to specific temperatures.

- Benefit : Provides precise temperature control necessary for accurate chemical reactions and tests.

- Fluxing and Cleaning:

- Application : In the preparation of metal samples for hallmarking, fluxing agents are often used to clean the metal. Hot plates can heat these agents to aid in their effectiveness.

- Benefit : Ensures that the metal is clean and free of impurities before hallmarking.

Overall Benefits in Hallmarking:

- Accuracy : Provides precise temperature control crucial for accurate testing and processing of precious metals.

- Efficiency : Speeds up processes like melting and sample preparation, leading to a more efficient hallmarking workflow.

- Consistency : Ensures that heating conditions are uniform, which is essential for reliable and repeatable results.